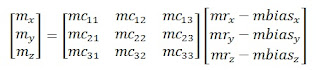

The following figure illustrates the interface between the Raymarine transducer and the microcontroller. With the regulated supply voltage now reduced from 8 to 7.25 V, the wind vane produces 2 analog signals (the green and blue wires), varying between 2.4 and 4.8 volts.

The analog signals are fed directly to two ADC (analog-to-digital) pins of the microcontroller. The microcontroller uses a 5 V volt reference to convert the signals to a number ranging from 0 to 1023.

This is the form of the signals produced when the vane is rotated through a complete turn from 0 (wind from the front of the boat) to 360 degrees, clockwise from above.

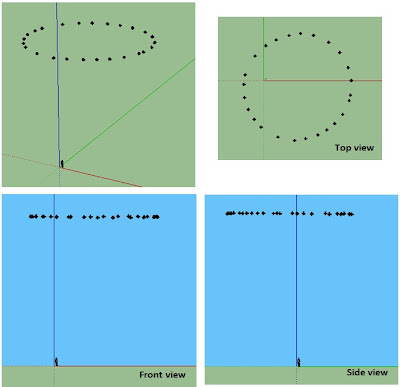

When the mast was down (instead of climbing up there), I manually rotated the vane and recorded the blue and green ADC signals at several angles around a full turn, first clockwise and then counterclockwise.

Then the green/blue pairs are graphed as X,Y points in Excel.

This may look like a circle, but it is in fact a slightly eccentric ellipse, with its axis tilted, and its center slightly off the main diagonal. The next step is to find the equation of the ellipse that best fits these points. For this step, we use the NLREG software which has a convenient example of fitting an ellipse to data points.

Parameter Final estimate

------------------ ------------------ Xcenter 741.363842

Ycenter 744.69208

Tilt Angle (T) 1.86167052 radian

Xdim 243.159241

Ydim 249.288046

The calibration technique consists in mapping the ellipse to a circle centered at the origin (0,0). For each green/blue measurement pair (x_green, y_blue), the apparent wind angle can then be calculated by the following procedure.

The equation reduces to:

And the measured apparent wind angle can be calculated as: